Has this ever happened to you?

That doesn't happen to us anymore.

Full-Arch BioToronto Prosthesis

The game-changing biocompatible prosthesis.

With 30 years of experience in the dental field, we have designed and developed the ideal solution to the challenges of traditional prostheses.

The BioToronto is the first full-arch implant supported prosthesis featuring an internal reinforcement made of PEEK, a biocompatible material with properties very similar to human bone.

The Issues with Traditional Toronto Prostheses

Rigidity

Fractures

Excessive weight

Lack of adaptability

Implant failures

Lack of comfort

Premature wear of dental elements

Poor adhesion of aesthetic materials

Fracture of the substructure

Decrease in vertical dimension

Detachment of dental elements

The Advantages of BioToronto

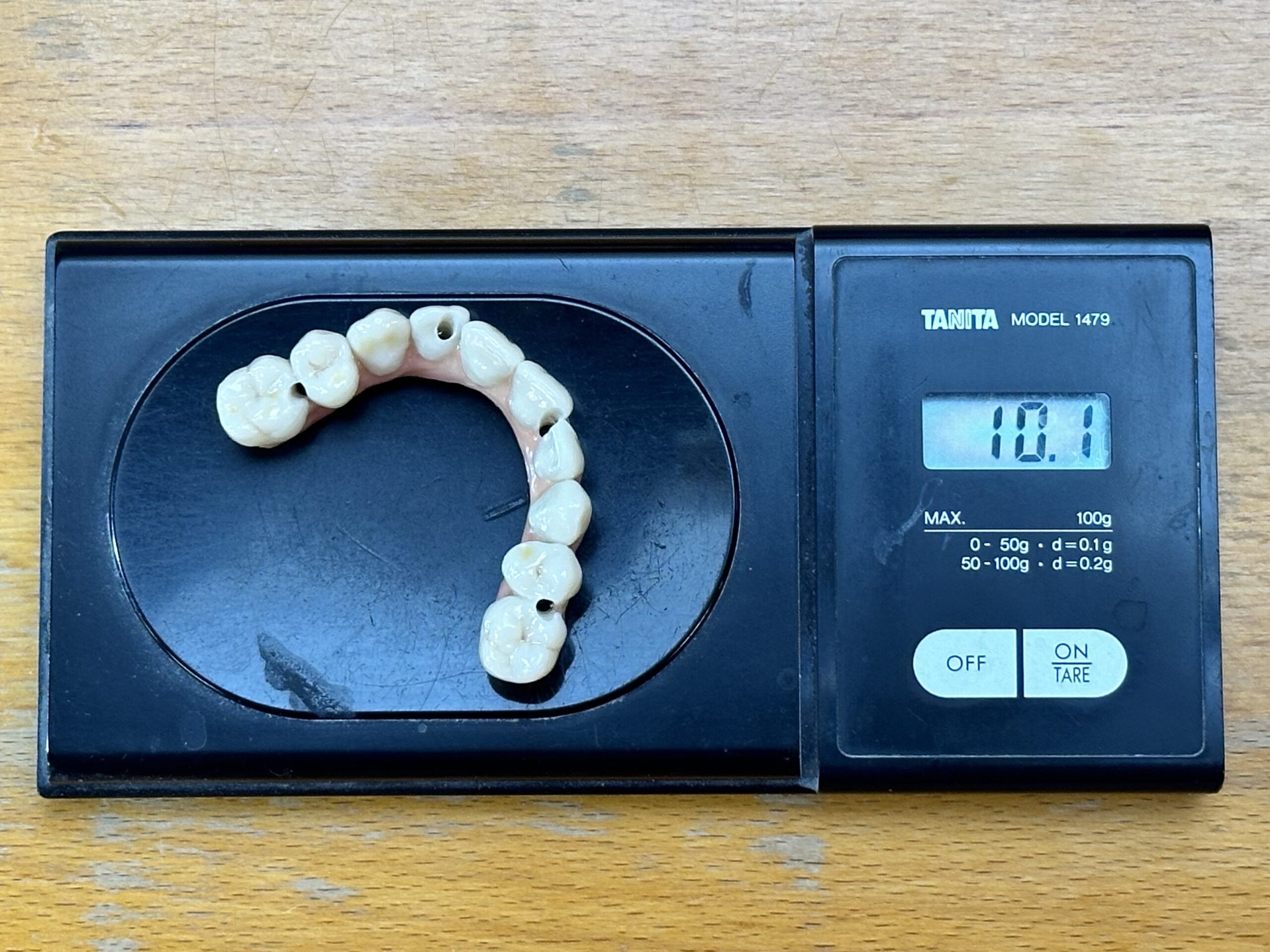

Weight

A BioToronto made of BioHPP weighs about 11 grams, one-third of traditional prostheses. This ensures that the patient feels comfortable as soon as it is installed.

Lower Wear

The BioToronto is made with more suitable materials for dental elements – lithium disilicate or zirconia – ensuring reduced wear.

Adaptability

The BioToronto offers better adaptability to the natural movements of the patient’s mouth and a longer-lasting durability over time.

Adhesion

The dental elements are made of ceramic or composite materials, depending on the requirements, ensuring maximum adhesion to the underlying structure.

Protection

Thanks to its features, the BioToronto prosthesis protects implants from posterior loads and limits abrasion.

Preservation

Characterized by elasticity similar to that of bone tissue, it is able to reduce the forces generated by MMF on the implants.

Testimonial from Clinicians

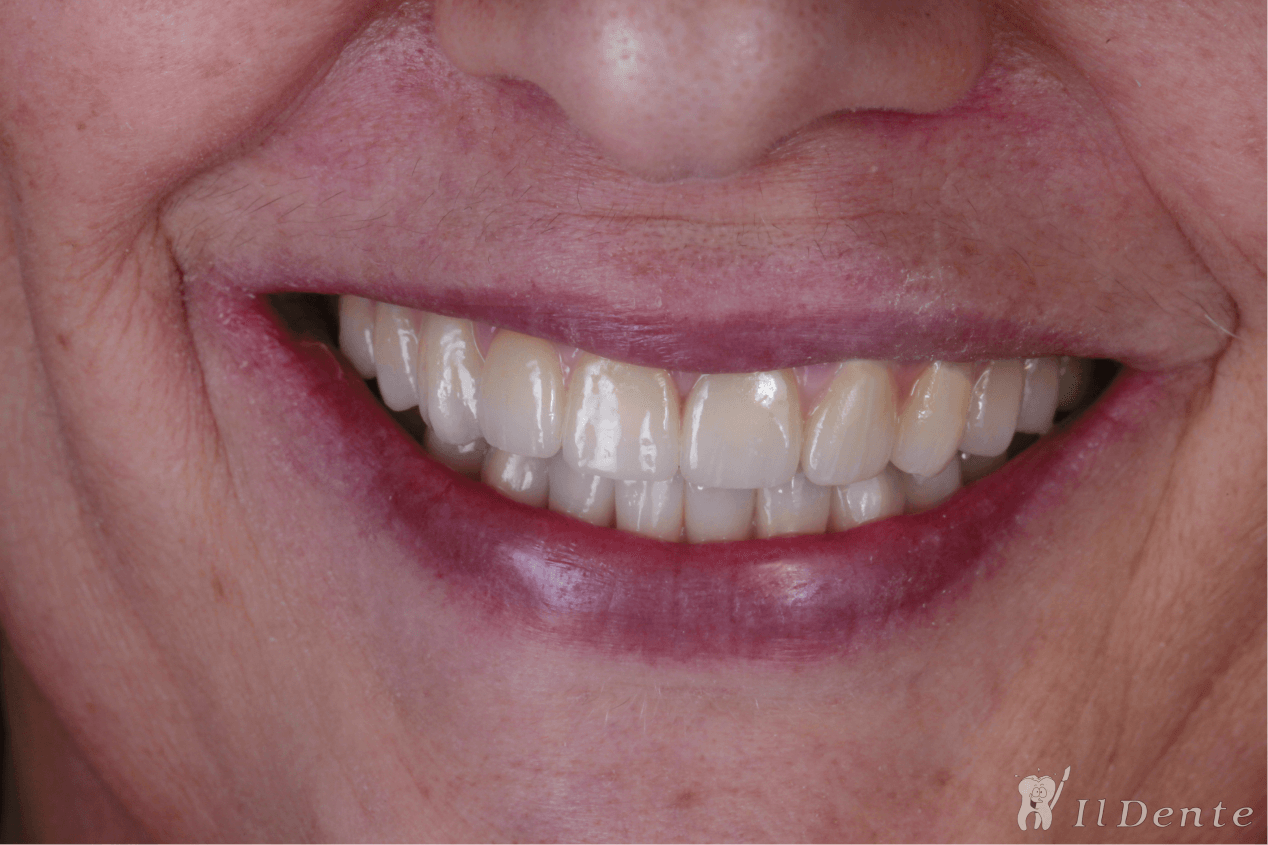

Dr. Luca Lavorgna presents a clinical case successfully treated with the use of BioToronto.

BioToronto, Two Opposing Arches

During the design of this complex prosthetic project on two opposing arches, Dr. Luca Lavorgna (Caserta) chose two BioToronto prostheses.

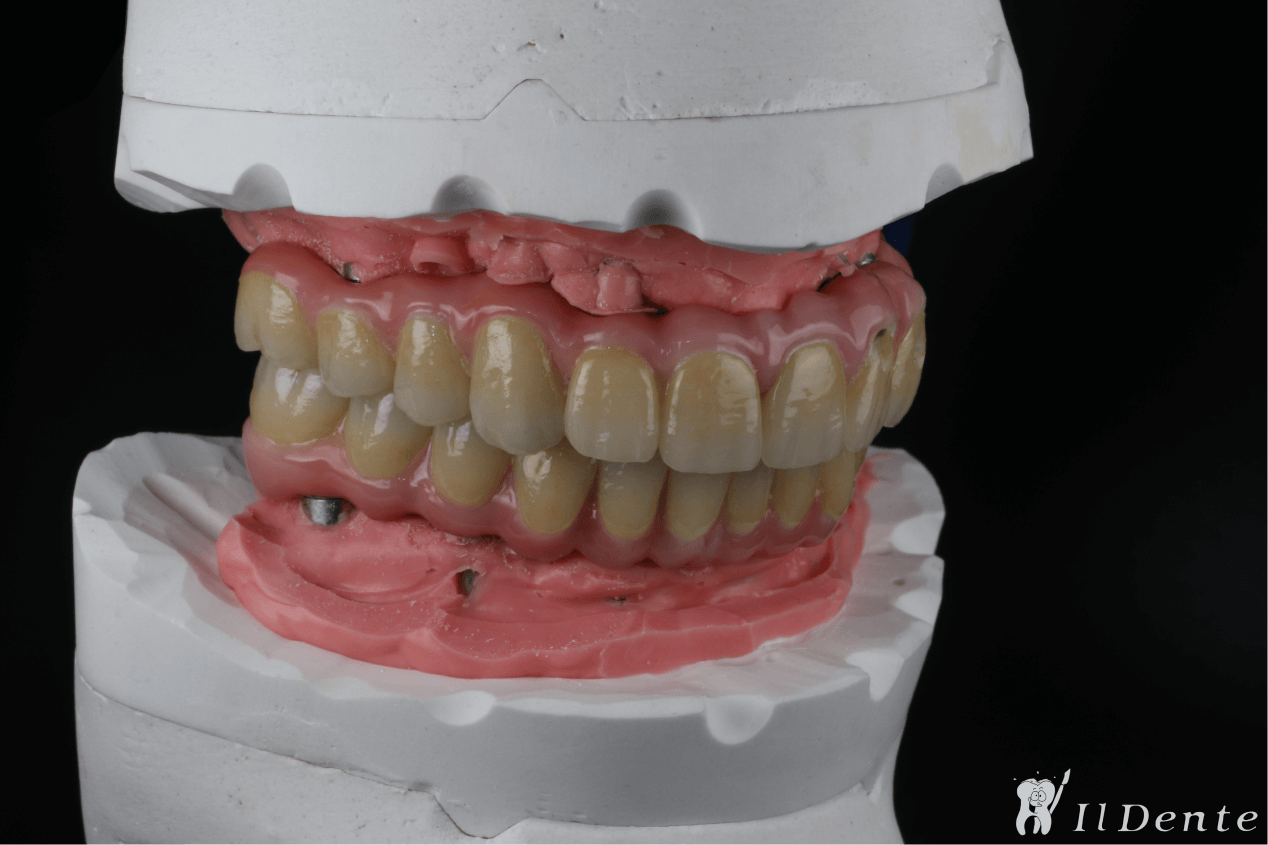

After waiting for the maturation of the newly inserted implants, we proceeded with the creation of two aesthetic-functional MockUps to verify that the implant positions transferred during the impression were correct, and that both aesthetics and function met the patient’s and client’s requirements.

To achieve the desired aesthetics, we used the flagship version of BioToronto, made with individual lithium disilicate dental elements and composite material for the gums.

BioToronto C, Upper Arch

In this case commissioned by the Turotti studio (San Maurizio Canavese, Turin), we started by creating an immediate loading provisional for the upper arch.

The request was to restore the most natural smile possible for this patient, focusing on the movement of the teeth.

Together with the client, we chose the BioToronto C version, featuring hybrid composite prototype dental elements, colored with surface colors, and composite material for the gums, to ensure a very high aesthetic result, characterized by unprecedented lightness and comfort.

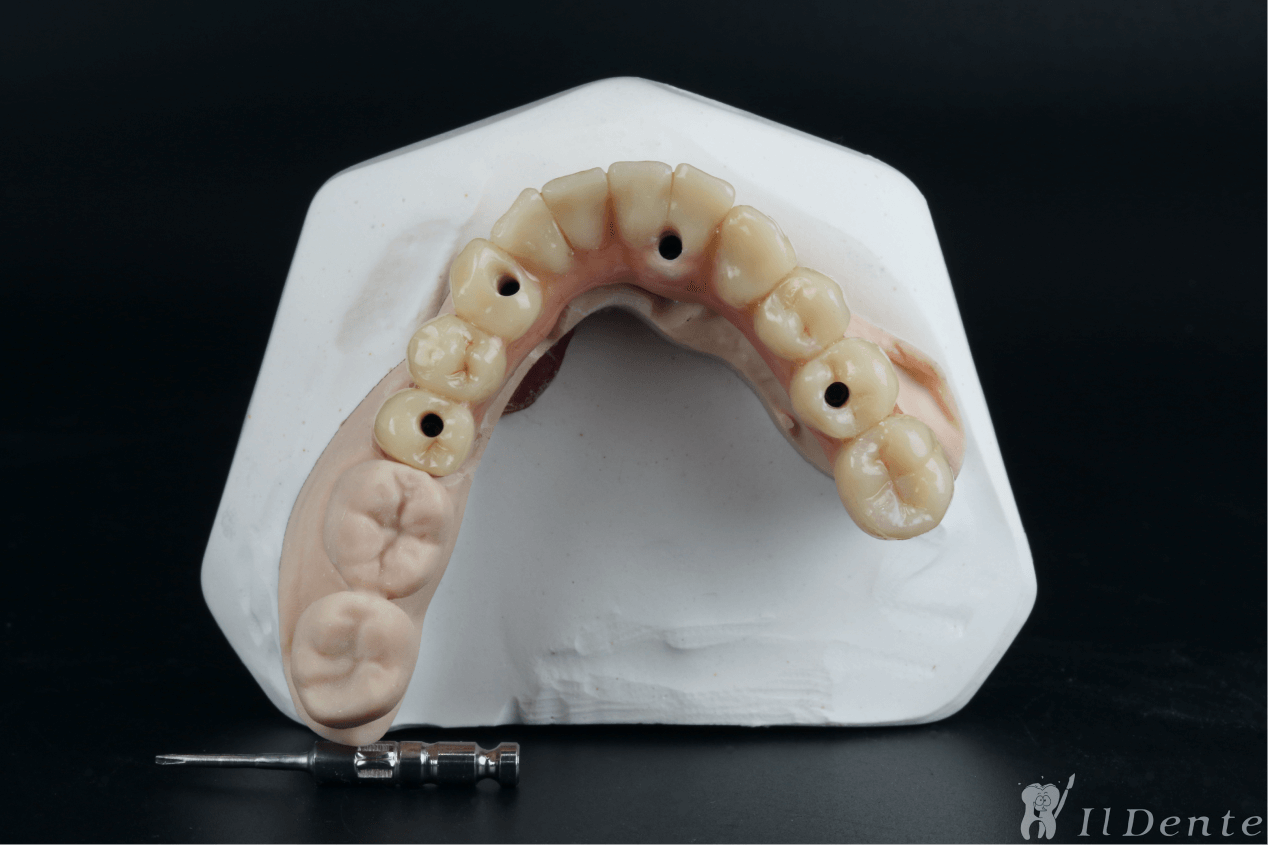

BioToronto, Upper Arch

For the design of a BioToronto, it is essential to go through an aesthetic and functional MockUp to zero in on any errors during the work phases.

Also in this case of upper BioToronto, made for the A-Dental practice (Turin, Italy), it was possible to arrive at an optimization of aesthetics, without neglecting function, precisely because of the use of two MockUps: an integral one to evaluate the overall aesthetics, and a purely aesthetic one for the fabrication of future crowns.

The expectation of aesthetics was exceeded through the use of lithium disilicate to make the crowns: a super-natural appearance characterized by unparalleled durability and comfort of excellence.

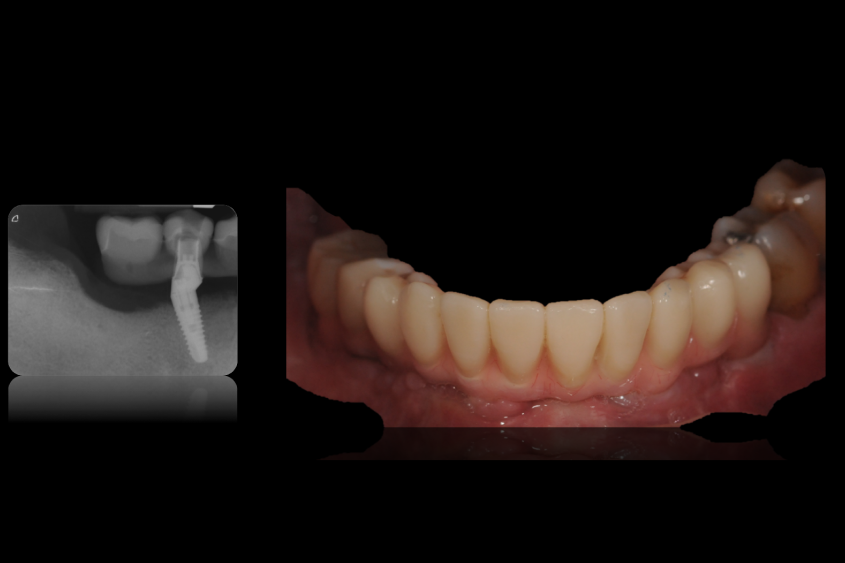

BioToronto, Lower Arch

Dr. Luca Ortensi (Bologna) tasked us with creating a lower BioToronto prosthesis: we started with a provisional, which was a skeletal prosthesis, used as a reference for space, dental element size, and centric relation.

Marco Ortensi’s laboratory created a “Test-Drive” to check the implant position and centric relation.

The choice of material for the dental elements was agreed upon based on the patient’s age and needs: we used a 3D-printed prototype composite, which was subsequently characterized, ensuring better maintenance of the vertical dimension compared to traditional PMMA.

The BioToronto Prosthesis protects implants from excessive masticatory load peaks, thereby extending their lifespan and improving adhesion to aesthetic and dental coatings.

Our Laboratory: Il Dente

Il Dente laboratory was founded on July 14, 1994, in Cirié, in the province of Turin, with a clear mission: to help dentists create the best prostheses for their patients by combining experience, craftsmanship, and technology.

This challenge still guides all the activities and decisions we make today.

Over these 30 years, we have supported dozens of dental practices and professionals with different needs in solving clinical cases, ranging from the most traditional to the most complex. We have witnessed the advent of new technologies and materials that have profoundly changed dental techniques and procedures. We have contributed to the stories of countless patients, successfully meeting their increasingly demanding expectations.

Our mission has led us to become more than just a dental laboratory: a team of professionals who ensure the creation of prostheses suitable for every need, both aesthetic and economic.

And it is in this context that the BioToronto prosthesis was born.

FAQ

Can’t find the answer to your question? Get in touch with us.

Many dental practices have already experienced detachment of dental elements from traditional Toronto prostheses. With BioToronto, you can forget about unpleasant situations or incidents. Additionally, you should know that the teeth are replaceable if needed, and the comfort experienced by the patient is unmatched.

No. The PEEK used for the substructure is not flexible: it has rigidity and an elastic modulus very similar to that of human bone. Its main feature is its ability to dissipate masticatory forces, preserving the implants over time.

Absolutely! We have a protocol for every need.

The two main protocols produce comparable results: it’s a clinical choice whether to proceed with a digital or analog workflow.

You can download our protocols here.

In the rare case of dental element fractures, all you need to do is follow our restoration protocol, and within a few days, your patient’s BioToronto will be as good as new.

In most cases, it will not be necessary to remove the BioToronto from the oral cavity.

We can use both composite and ceramic materials, such as reinforced PMMA, 3D- printed composites, lithium disilicate, and zirconia. Depending on the clinical and economic needs of the professional, we create BioToronto with different characteristics, but the same core quality.

To provide you with as much information as possible, we have prepared a presentation that details the history, features, and benefits of the BioToronto prosthesis.

You can find it below. For more details on the operational stages, we invite you to receive the protocol via email in the section below.